Fuel pump relay maintenance represents a critical yet often overlooked aspect of automotive care that directly impacts vehicle reliability and performance. These small electrical components control the power supply to fuel pumps, ensuring proper engine operation across all driving conditions. Regular cleaning and maintenance prevent costly roadside breakdowns and expensive fuel system repairs. Wanna Taxi understands the importance of reliable vehicle operation, emphasizing preventive maintenance for fleet vehicles and personal transportation.

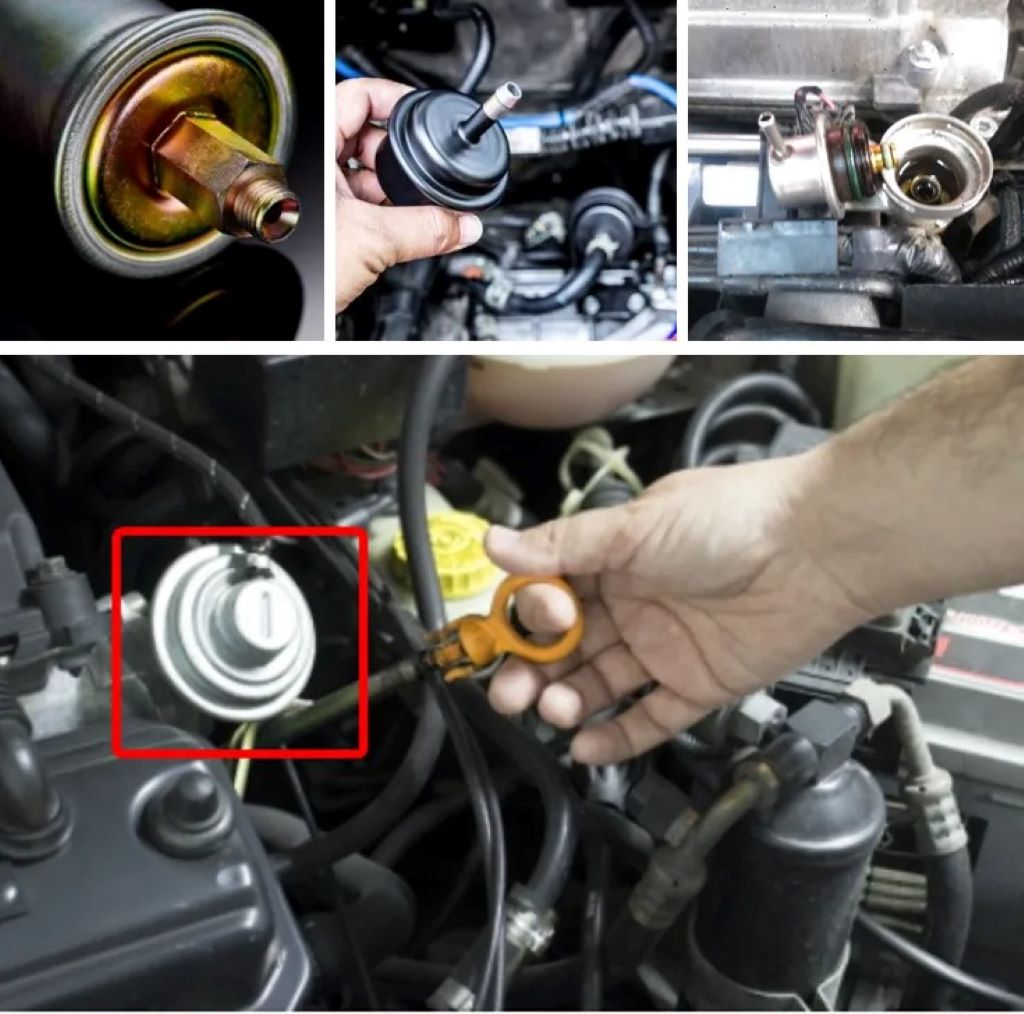

Modern vehicles depend heavily on electronic fuel injection systems that require consistent fuel pressure to operate efficiently. The fuel pump relay serves as the electrical switch that activates the fuel pump when needed. However, contamination and corrosion can cause relay contacts to fail, leading to intermittent operation or complete fuel system shutdown.

Understanding the relationship between the fuel pump relay and receiver systems helps mechanics diagnose and prevent common fuel delivery problems. Therefore, proper cleaning procedures extend relay life while maintaining optimal fuel system performance and vehicle reliability.

Understanding Fuel Pump Relay Components

Internal Relay Construction

Fuel pump relays contain several key components including electromagnetic coils, contact points, springs, and protective housings. The electromagnetic coil creates magnetic fields that operate the switching mechanism. Additionally, contact points handle the actual current flow to fuel pump circuits.

Spring mechanisms return relay contacts to their default positions when power is removed from the control circuit. These springs must maintain proper tension and alignment for reliable operation. However, contamination can interfere with spring movement and cause relay malfunction.

Protective housings shield internal components from environmental contamination while providing electrical insulation. Housing integrity affects both electrical safety and component longevity. Therefore, housing damage or contamination requires immediate attention during maintenance procedures.

Electrical Contact Systems

Relay contact points carry significant electrical current during fuel pump operation. These contacts must maintain low resistance connections to prevent voltage drops and power losses. Additionally, clean contacts ensure reliable switching action and prevent intermittent operation problems.

Contact materials typically consist of silver alloys or other conductive metals designed for electrical switching applications. These materials resist corrosion but can still accumulate contamination over time. However, proper cleaning techniques restore contact performance without damaging delicate surfaces.

Arcing between contacts during switching operations can create carbon deposits and surface irregularities. These deposits increase resistance and reduce switching reliability. Therefore, regular cleaning removes accumulated contamination before it causes performance problems.

Common Contamination Sources

Environmental Factors

Engine bay environments expose fuel pump relays to various contaminants including dirt, oil vapors, and moisture. Heat cycling causes expansion and contraction that can allow contamination entry. Additionally, vibration and shock loads can accelerate wear and contamination accumulation.

Road salt and chemical exposure create corrosive conditions that attack relay components and connections. Winter driving conditions particularly increase contamination risks. However, proper cleaning removes these contaminants before permanent damage occurs.

Age-related degradation affects housing seals and allows contamination entry into previously protected areas. Older vehicles require more frequent relay maintenance due to deteriorated sealing systems. Therefore, maintenance intervals should decrease as vehicles age.

Internal Contamination Sources

Electrical arcing during normal switching operations creates carbon particles that accumulate on contact surfaces. These particles increase resistance and reduce switching reliability. Additionally, contact material erosion can create metallic debris that interferes with operation.

Lubricants and sealants used in relay manufacturing can break down over time and create sticky residues. These residues attract additional contamination and interfere with moving parts. However, proper cleaning solvents remove both original lubricants and accumulated debris.

Moisture infiltration can cause corrosion of internal components and create conductive paths between circuits. This moisture often comes from temperature cycling and humidity changes. Therefore, thorough cleaning and drying procedures prevent moisture-related problems.

Safety Precautions and Preparation

Electrical Safety Measures

Disconnect battery negative terminal before beginning any fuel system electrical work. This prevents accidental short circuits and protects both technician and vehicle systems. Additionally, wait several minutes for capacitors to discharge before handling electrical components.

Use insulated tools when working with electrical connections to prevent accidental shorts or ground faults. Proper tool insulation protects both technician and sensitive electronic systems. However, verify tool condition before each use to ensure insulation integrity.

Work in well-ventilated areas when using cleaning solvents to prevent vapor accumulation and health hazards. Some cleaning chemicals require special ventilation and personal protective equipment. Therefore, read all material safety data sheets before beginning work.

Fire Prevention Protocols

Remove all ignition sources from work areas when handling fuel system components. Fuel vapors can ignite from seemingly minor spark sources including static electricity. Additionally, have appropriate fire extinguishing equipment readily available.

Avoid smoking or open flames in areas where fuel system work is performed. Fuel vapors can travel significant distances and ignite unexpectedly. However, proper ventilation and vapor control reduce fire risks substantially.

Store contaminated cleaning materials and waste products in appropriate containers away from heat sources. Some cleaning solvents create fire hazards even after use. Therefore, proper waste disposal prevents fire hazards and environmental contamination.

Required Tools and Materials

Cleaning Equipment

Acquire appropriate cleaning solvents designed for electrical contact cleaning applications. These solvents must remove contamination without damaging relay components or leaving residues. Additionally, use solvents that evaporate completely and don’t conduct electricity.

Small brushes with soft bristles help remove stubborn contamination without damaging delicate contact surfaces. Toothbrushes or specialized electrical brushes work well for most applications. However, avoid abrasive materials that could damage contact plating or surface finishes.

Compressed air systems provide effective methods for removing loose contamination and drying cleaned components. Use clean, dry compressed air to prevent introducing additional contamination. Therefore, filter and dry compressed air systems before use on electrical components.

Measurement and Testing Tools

Digital multimeters verify relay electrical performance before and after cleaning procedures. These instruments measure resistance, voltage, and continuity to confirm proper operation. Additionally, multimeters help identify performance improvements achieved through cleaning.

Contact resistance testers provide precise measurements of relay contact performance. These specialized tools detect resistance increases that indicate contamination or wear. However, standard multimeters can provide adequate measurements for most cleaning verification needs.

Relay testers simulate actual operating conditions to verify proper switching action and timing. These devices help identify intermittent problems that might not appear during static testing. Therefore, dynamic testing confirms that cleaning procedures restored proper relay operation.

Step-by-Step Cleaning Procedure

Relay Removal and Identification

Locate the fuel pump relay in the vehicle’s fuse and relay box using the owner’s manual or service information. Relays are typically labeled or identified by position diagrams. Additionally, photograph relay positions before removal to ensure correct reinstallation.

Remove the relay by gently pulling straight up while rocking slightly from side to side. Avoid excessive force that could damage relay terminals or socket connections. However, some relays may require special removal tools for proper extraction.

Inspect relay terminals and socket connections for corrosion, damage, or loose connections. Clean socket connections using appropriate electrical contact cleaner if contamination is present. Therefore, address both relay and socket contamination for optimal performance.

Initial Inspection and Assessment

Examine relay housing for cracks, damage, or contamination entry points. Damaged housings may require relay replacement rather than cleaning. Additionally, document housing condition for future reference and maintenance planning.

Check terminal condition and alignment before beginning cleaning procedures. Bent or damaged terminals may prevent proper socket connection even after cleaning. However, minor terminal alignment issues can often be corrected during cleaning procedures.

Perform initial electrical measurements to establish baseline performance before cleaning. These measurements provide objective criteria for evaluating cleaning effectiveness. Therefore, document all measurements for comparison with post-cleaning results.

Contact Cleaning Process

Apply appropriate electrical contact cleaner to all relay terminals and internal contact points if accessible. Allow cleaner to penetrate contamination for recommended dwell time. Additionally, use minimal cleaner amounts to prevent over-wetting and component damage.

Gently brush contact surfaces using soft-bristled brushes to remove stubborn contamination. Work carefully to avoid damaging contact plating or surface finishes. However, some contamination may require multiple cleaning cycles for complete removal.

Rinse cleaned areas with fresh solvent to remove dissolved contamination and cleaning residues. Ensure complete contamination removal before proceeding to drying procedures. Therefore, thorough rinsing prevents recontamination during drying and testing.

Drying and Final Preparation

Use compressed air to remove excess cleaning solvent and accelerate drying processes. Direct air flow carefully to avoid forcing contamination into inaccessible areas. Additionally, ensure complete moisture removal before electrical testing or installation.

Allow adequate drying time for all cleaning solvents to evaporate completely. Residual solvents can cause electrical problems or attract additional contamination. However, heated drying chambers can accelerate drying for production environments.

Inspect cleaned components for remaining contamination or damage that might require additional attention. Some contamination may become visible only after initial cleaning removes surface deposits. Therefore, thorough inspection after cleaning ensures complete contamination removal.

According to the Environmental Protection Agency, proper disposal of automotive cleaning solvents and contaminated materials helps protect environmental quality and public health.

Testing and Verification Procedures

Electrical Performance Testing

Measure contact resistance using precise instruments to verify cleaning effectiveness. Clean contacts should show minimal resistance values within manufacturer specifications. Additionally, compare measurements to baseline values recorded before cleaning.

Test relay coil resistance and continuity to ensure cleaning procedures didn’t damage electromagnetic components. Coil damage can prevent relay operation even with clean contacts. However, coil problems usually indicate relay replacement rather than continued cleaning efforts.

Verify proper switching action using relay testers or controlled power applications. Dynamic testing reveals intermittent problems that static measurements might miss. Therefore, comprehensive testing confirms that cleaning restored full relay functionality.

Functional Verification

Install cleaned relays in vehicle systems and verify proper fuel pump operation. Listen for fuel pump activation during key-on sequences and engine cranking. Additionally, monitor fuel pressure and engine performance for proper operation indicators.

Test relay performance under various operating conditions including cold starts, hot restarts, and extended operation periods. Some contamination effects only appear under specific operating conditions. However, comprehensive testing reveals problems that might cause future failures.

Document test results and performance improvements achieved through cleaning procedures. This documentation helps establish maintenance intervals and procedures for similar applications. Therefore, proper record keeping improves future maintenance effectiveness and reliability.

Preventive Maintenance Strategies

Regular Inspection Schedules

Establish relay inspection intervals based on vehicle age, operating conditions, and previous failure history. Newer vehicles may require less frequent inspection than older units with known contamination problems. Additionally, severe service conditions may require shortened maintenance intervals.

Include relay inspection in routine maintenance procedures such as oil changes or tune-ups. Regular inspection catches developing problems before they cause failures. However, inspection procedures must be systematic to ensure consistent coverage of all critical relays.

Document inspection findings and maintenance actions for trend analysis and failure prediction. Historical data helps identify patterns and optimize maintenance intervals. Therefore, proper documentation improves overall maintenance program effectiveness.

Environmental Protection Methods

Apply protective coatings or sealants to relay housings in severe environments. These treatments help prevent contamination entry while maintaining electrical performance. Additionally, protective treatments can extend service life in corrosive or contaminated environments.

Relocate relays away from contamination sources when possible during vehicle modifications or repairs. Better mounting locations reduce contamination exposure and extend component life. However, relay relocation must not interfere with proper electrical operation or accessibility.

Install protective covers or shields around relay boxes in severe service applications. These modifications provide additional protection while maintaining accessibility for maintenance. Therefore, environmental protection measures reduce maintenance requirements and improve reliability.

Advanced Cleaning Techniques

Ultrasonic Cleaning Methods

Ultrasonic cleaning systems provide thorough contamination removal from complex relay geometries. These systems use high-frequency vibrations to dislodge contamination from inaccessible areas. Additionally, ultrasonic cleaning reduces manual labor while improving cleaning consistency.

Select appropriate cleaning solutions for ultrasonic applications based on contamination types and relay materials. Some solvents work better with ultrasonic agitation while others may cause damage. However, proper solution selection enhances cleaning effectiveness while protecting components.

Control ultrasonic cleaning parameters including frequency, power, and exposure time to prevent component damage. Excessive exposure can damage delicate components or remove protective coatings. Therefore, establish proper parameters through testing and manufacturer recommendations.

Chemical Restoration Processes

Specialized contact restoration chemicals can remove corrosion and restore electrical performance to heavily contaminated relays. These chemicals often contain acids or other reactive compounds that require careful handling. Additionally, neutralization procedures may be required after treatment.

Apply restoration chemicals according to manufacturer instructions and safety protocols. Improper application can cause component damage or create safety hazards. However, proper use of restoration chemicals can salvage heavily contaminated relays.

Follow restoration chemical treatments with thorough rinsing and neutralization procedures. Residual chemicals can cause ongoing corrosion or electrical problems. Therefore, complete chemical removal is essential for successful restoration.

Quality Control and Documentation

Performance Standards

Establish acceptable performance criteria based on manufacturer specifications and industry standards. These criteria provide objective measures for cleaning success and relay acceptability. Additionally, performance standards help identify relays requiring replacement rather than continued cleaning efforts.

Compare post-cleaning performance to original specifications rather than just pre-cleaning conditions. Some contamination effects may be irreversible and indicate relay replacement needs. However, significant performance improvements justify cleaning efforts and costs.

Track performance trends over multiple cleaning cycles to identify declining relay performance. Relays showing reduced cleaning response may be approaching end of service life. Therefore, trend analysis helps predict replacement needs and optimize maintenance schedules.

Record Keeping Systems

Maintain detailed records of cleaning procedures, performance measurements, and service history for each relay. This documentation supports warranty claims and helps optimize maintenance procedures. Additionally, service records help identify problem patterns and improvement opportunities.

According to Consumer Reports, proper maintenance documentation helps vehicle owners track service history and identify recurring problems that may indicate design issues or service deficiencies.

Use standardized forms and procedures to ensure consistent documentation across multiple technicians and service events. Standardization improves data quality and facilitates analysis. However, documentation systems must balance completeness with practical usability.

Conclusion

Professional fuel pump relay cleaning procedures can significantly extend component life while maintaining optimal vehicle performance and reliability. Understanding relay construction, contamination sources, and proper cleaning techniques enables effective maintenance programs. Additionally, systematic approaches to cleaning, testing, and documentation ensure consistent results and continuous improvement.

Key success factors include proper safety procedures, appropriate cleaning materials, thorough testing verification, and comprehensive documentation. Regular maintenance intervals prevent minor contamination from developing into major reliability problems. However, knowing when to replace rather than clean components prevents wasting time on irreparable units.

Preventive maintenance strategies that combine regular inspection, environmental protection, and systematic cleaning provide the best long-term value. Advanced cleaning techniques and quality control procedures enhance effectiveness while ensuring safety and reliability. Therefore, comprehensive relay maintenance programs contribute significantly to overall vehicle dependability and performance.

Frequently Asked Questions

How often should fuel pump relays be cleaned? Cleaning intervals depend on vehicle age and operating conditions, typically every 2-3 years for normal service. Severe conditions like dusty environments or extreme temperatures may require annual cleaning. Additionally, cleaning frequency should increase as vehicles age and sealing degrades.

Can damaged relay contacts be repaired through cleaning? Minor surface contamination and corrosion can often be removed through proper cleaning procedures. However, severely pitted or burned contacts usually require relay replacement. Therefore, inspection determines whether cleaning or replacement provides the better solution.

What cleaning solvents work best for fuel pump relays? Electrical contact cleaners specifically designed for automotive applications provide the best results. Avoid petroleum-based solvents that can damage plastic components or leave residues. Additionally, ensure solvents evaporate completely and don’t conduct electricity.

How do I know if relay cleaning was successful? Measure contact resistance before and after cleaning to verify improvement. Successful cleaning typically reduces resistance significantly and restores proper switching action. However, dynamic testing under actual operating conditions provides the best verification of cleaning effectiveness.

Should I clean the relay socket connections too? Yes, socket contamination can cause the same problems as dirty relay contacts. Clean socket terminals using appropriate electrical contact cleaner and inspect for corrosion or damage. Therefore, addressing both relay and socket contamination ensures optimal electrical connection and performance.

Read More:

Your Tires, Your Way: Making the Right Choice

High Visibility, Safety Compliant, Chevron Kits for All Vehicles

+ There are no comments

Add yours